Engineering tsheb fais fab tswj lub thawv

Tuam txhab txhaj tshuaj molding Service

Xuzhou Lichi Intelligent Technology Co., Ltd.Tshwj xeeb txhaj tshuaj molding PP PE POM PA6 PA1010 PPS PEEK ABS thiab lwm yam khoom siv yas yas:

● Tsis muaj kua nplaum nyob ib ncig ntawm qhov chaw txhaj tshuaj, tsis txaus cov pwm tshuaj ntsuam xyuas thiab kev daws teeb meem

● Batch pem hauv ntej (burr) ua rau kev tsom xam thiab kev daws teeb meem

● Ua rau kev tsom xam thiab kev daws ntawm qhov chaw shrinkage thiab shrinkage (lub tshuab nqus tsev npuas) ntawm kev txhaj tshuaj molded qhov chaw

● Cov kab nyiaj (khoom siv, dej), hlawv, roj kab tsom xam thiab kev daws teeb meem

● Ua rau kev soj ntsuam thiab kev daws teeb meem ntawm cov dej ripples thiab ntws cov cim ntawm qhov chaw txhaj tshuaj molded

● Kev tshuaj xyuas qhov ua rau thiab kev daws teeb meem ntawm cov cim dej (cov cim fusion) thiab cov cim dav hlau (cov cim nab) ntawm qhov chaw txhaj tshuaj molded

● Txhaj qhov chaw nto tawg (kav), sab saum toj dawb (sab saum toj tawg) ua rau kev tsom xam thiab kev daws teeb meem

● Txhaj molding qhov chaw nto xim sib txawv, tsis zoo luster, sib xyaw xim, dub bar, dub qhov chaw ua rau kev tsom xam thiab kev daws teeb meem

● Ua rau kev tsom xam thiab kev daws teeb meem ntawm warping deformation thiab sab hauv kev ntxhov siab tawg ntawm qhov chaw txhaj tshuaj

● Ua rau kev tsom xam thiab kev daws qhov sib txawv ntawm qhov sib txawv ntawm qhov txhaj tshuaj

● Kev tshuaj xyuas yog vim li cas rau kev nplaum pwm, luag (strain), luag cov tshuaj pleev xim dawb thiab cov kev daws teeb meem

● Tsis muaj pob tshab ntawm qhov chaw txhaj tshuaj, lub zog tsis txaus (nkig tawg) ua rau kev tsom xam thiab kev daws teeb meem

● Ua rau kev tsom xam thiab kev daws teeb meem ntawm qhov chaw txias thiab tev tawm (stratification) ntawm qhov chaw txhaj tshuaj molded

● Txhaj tshuaj molding qhov chaw hlau ntxig rau qhov phem ua rau kev tsom xam thiab kev daws teeb meem

● Ua rau kev soj ntsuam thiab txhim kho kev ntsuas ntawm lub qhov ntswg salivation (kua ntswg), kua nplaum, kos duab kos, nozzle thaiv, pwm qhib nyuaj

● Siv CAE pwm flow analysis technology kom sai thiab zoo daws qhov teeb meem ntawm qhov chaw txhaj tshuaj

Optimization tsim:

● Txhaj pwm qauv, muaj pes tsawg leeg, kev faib tawm thiab kev ua haujlwm;

● Optimized tsim ntawm lub rooj vag system ( rooj vag, khiav, txias zoo, thiab lwm yam.)

● Kev tsim kho kom zoo ntawm lub tshuab ua kom txias (dej, diaphragm, beryllium lub tog raj kheej, thiab lwm yam)

● Shrinkage tus nqi teeb tsa thiab hloov kho

● Kev sib raug zoo ntawm cov txheej txheem pouring, txias system, pwm qauv thiab kev txhaj tshuaj molding txheej txheem

● Pwm installation, commissioning thiab tu

● Kev siv dej chiller thiab pwm kub tshuab los tswj cov txheej txheem

● Siv CAE pwm flow tsom tshuab rau pwm optimization tsim

Cov kws tshaj lij kev lag luam, txais tos hu rau, kev sab laj hais, los npaj kev tsim kho.

Khoom nta thiab lub tuam txhab zoo

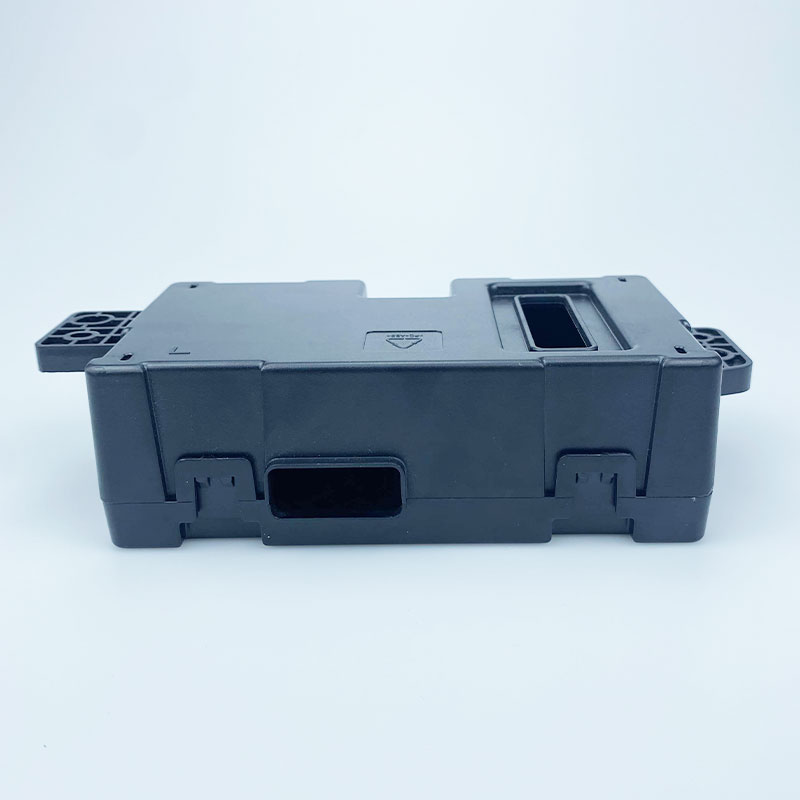

ABS Electronic Housing Case, chaw taws teeb tswj yias txhaj molded ib feem,

Textured nto.

Lub tes tsho ejection.

Ntau lifters.

Banana gate auto cut runner design.

High polishing concave logo cim.

Chaw tsim tshuaj paus muab ncaj nraim

Ntau yam specifications

Tus nqi yog tsim nyog

Tsom ntsoov rau qhov zoo

Ua customized

ruaj khov